China Nema 23 stepper motor suppliers introduce you to stepper motors

As China Nema 23 stepper motor supplier, I'm here to introduce you to stepper motors. A Stepper motor is an open-loop control element stepper motor that converts electrical pulse signal into angular displacement or line displacement by controlling the order, frequency, and quantity of electrical pulse applied on the motor coil, it can control the steering, speed, and rotation angle of the stepping motor. With a linear motion actuator or gearbox device, more complex and precise linear motion control requirements can be achieved.

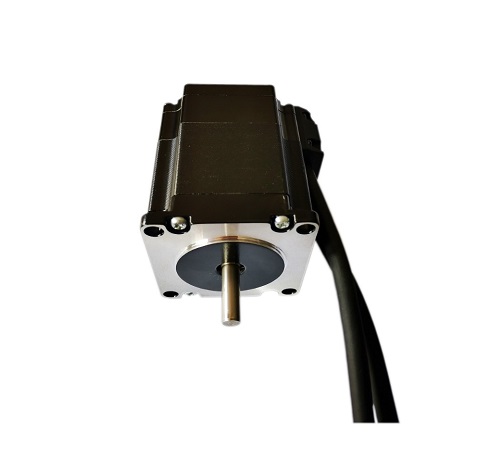

The basic structure of the Stepper Motor:

Stepper motors manufactured by China Nema 23 stepper motor suppliers are generally composed of front and rear end covers, bearings, center-shafts, rotor cores, stator cores, stator components, corrugated washers, screws, etc. . It uses electromagnetism to convert electrical energy into mechanical energy, which is driven by a coil wound around the cogging of a motor stator. Normally, a wire wound in a coil is called a solenoid, whereas, in an electrical machine, the wire wound around the stator cogging is called a winding, coil, or phase.

Stepper motor working principle:

According to the external control pulse and direction signal, the stepper motor driver, through its internal logic circuit, controls the winding of the stepper motor to be energized forward or reverse in a certain time sequence, so that the motor can rotate forward or reverse, or locked.

Take the 1.8-degree two-phase stepping motor as an example: when the two-phase windings are energized and excited, the motor output shaft will be stationary and locked position. The maximum torque to keep the motor locked at the rated current is the holding torque. If the current in one of the phase windings changes direction, the motor will rotate one step (1.8 degrees) in a given direction. Similarly, if the current in the other winding changes direction, the motor will rotate one step (1.8 degrees) in the opposite direction. When the current through the coil winding in order to change the direction of excitation, then electricity, opportunity along the direction of a given continuous rotation step, running precision is very high. For 1.8 degrees two-phase stepper motor rotation needs 200 steps.

The two-phase stepping motor has two types of winding: bipolar and unipolar. There is only one winding in each phase of the bipolar motor. When the motor rotates continuously, the current will be changed to excitation in turn in the same coil. There are two opposite-polarity windings on each phase of the unipolar motor. When the motor rotates continuously, it is only necessary to alternately energize and excite two windings on the same phase. Drive circuit design, design requires only four electronic switches. In the bipolar drive mode, the output torque of the motor in the bipolar drive mode is about 40% higher than that in the unipolar drive mode, because the windings of each phase are 100% excited.

The above is about the contents of the stepper motor. Yunkong Electronics is a China NEMA 23 stepper motor supplier. In the production of stepping motors has more than 20 years of production experience. If you want to know more, you can contact us directly.