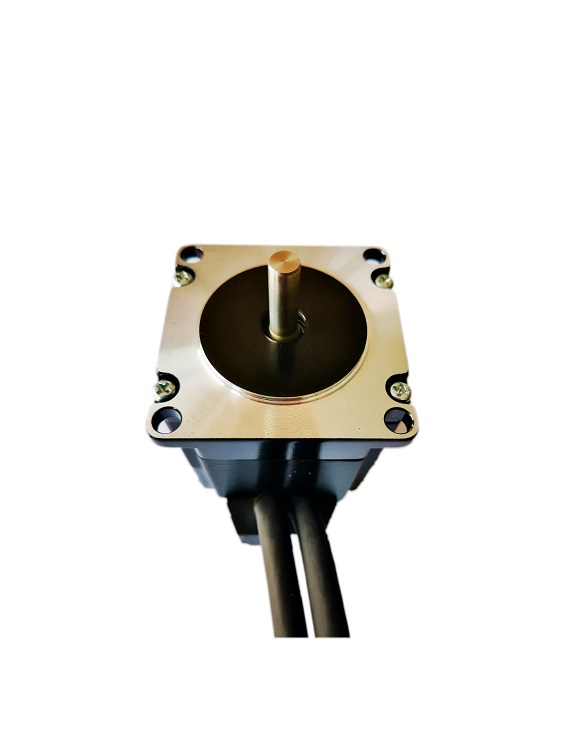

China Nema 23stepper motor manufacturers answers frequently asked questions about stepper motor

As one of China Nema 23 stepper motors manufacturers, I'm here to answer some frequently asked questions about stepper motors. If you are interested, please read on!

1. Why does the torque of the stepper motor decrease with speed?

When the stepper motor rotates, the inductance of each phase winding of the motor will form a reverse EMF. The higher the frequency, the greater the reverse EMF. Under its action, the phase current decreases with the increase in frequency (or speed), which leads to a decrease in torque.

2. Why is the stepper motor able to operate normally at low speeds, but unable to start above a certain speed, accompanied by a howling sound?

Stepper motor produced by China Nema 23stepper motor manufacturers has one technical parameter: no-load starting frequency, that is, the pulse frequency at which the stepper motor can start normally under no-load conditions. If the pulse frequency is higher than this value, the motor can not start normally, and loss of step or rotation may occur.

The startup frequency should be lower under load. If the motor is to rotate at high speed, the pulse frequency should be accelerated, that is, the starting frequency is low, and then by a certain acceleration to the desired high frequency (motor speed from low to high speed).

3. How to overcome the vibration and noise of a two-phase hybrid stepper motor at low speed?

Stepper motor low-speed rotation vibration and noise are its inherent shortcomings, but generally can be used to overcome the following solutions:

A. If the stepper motor is working in the resonance region, it can avoid the resonance region by changing the reduction ratio and another mechanical transmission.

B. The most common and easiest way to do this is to use a drive with a subdivision function.

C. Switch to a stepper motor with a smaller step angle, such as a three-phase or five-phase stepper motor.

D. Switching to an AC servo motor can almost completely overcome the vibration and noise, but the cost is higher.

Don't. Magnetic dampers are added to the motor shaft. There are some such products on the market, but the mechanical structure has changed greatly.

These are just a few common questions about stepper motors. Yunkong Electronics is a China NEMA 23stepper motors manufacturer. I have a lot of experience in manufacturing stepper motors, if you have any other questions or needs, please feel free to contact us.